Scrap Processors

October 1, 2024

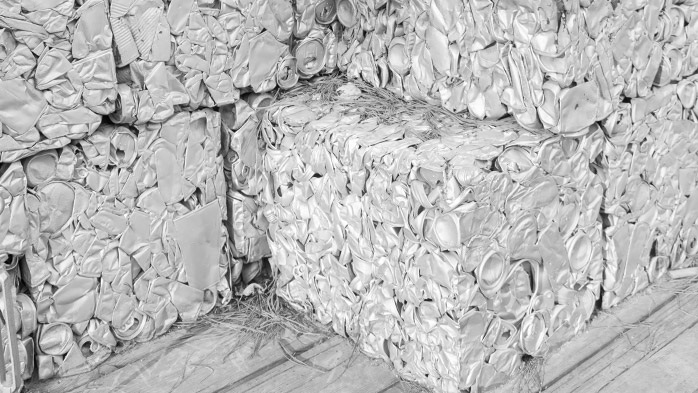

Hydro, Padnos aluminum JV to 'dig deeper in the pile'

Written by Stephanie Ritenbaugh

In an effort to keep more aluminum in the production stream, Norwegian aluminum and renewable energy company Hydro and scrap management enterprise Padnos have started up their new automated aluminum sorting technology in Michigan.

“Aluminum is infinitely recyclable, but far too much of it ends up in landfills. The new sorting machine allows us to dig deeper in the pile and let more aluminum get a new lease on life. Advanced recycling is good for the environment, it’s good for the climate and it’s good for business,” says Duncan Pitchford, president of Hydro Aluminum Metals USA, in a statement.

The plant, dubbed Alusort LLC, supplies Hydro’s Cassopolis and Henderson recycling plants with raw material for large-scale production of low-carbon Hydro CIRCAL, which is Hydro’s line of recycled aluminum with minimum 75% post-consumer scrap content.

The Alusort 50-50 joint venture was established in November with a plan to install a HySort sorting machine at Padnos’ existing sorting hub in Grandville, Michigan. The capital investment for Hydro was estimated at around USD $4 million. The machine has an annual sorting capacity of 20,000 tonnes of aluminum scrap per year, producing recycled alloys aimed at the U.S. automotive, building and construction, and other key markets.

Hydro said the project “answers the call for putting valuable materials from cars, buildings, electronic equipment or other consumer goods to good use in a growing domestic market rather than sending it to landfills or exporting it overseas.”

“The ramp-up of production will make a real difference for American manufacturing and, we hope, encourage everyone in the recycling industry to continue innovating toward a more circular, sustainable economy,” says Sam Padnos, Manager of Nonferrous Trading at Padnos.